by Good News Lab | Jun 13, 2019 | Jendamark Junction

A pioneering partnership with Mahindra Electric (MEML) has seen Jendamark delivering India’s first automated assembly line for the power electronics that drive the brand’s electric vehicles.

Jendamark has proved a reliable partner in supporting MEML’s goals by delivering state-of-the-art, Industry 4.0-enabled assembly lines and solutions to their world-class facility in Bangalore. Entering the innovative and exciting world of electric vehicles, Jendamark Techcellency (JMKT) has developed a strong partnership with Mahindra, the country’s front runner and pioneer in the field.

“We believe that change is constant. Although the electric car infrastructure in India is still developing, most companies have strategies in place and are investing in the electric car market,” says Jendamark Techcellency CEO Himanshu Jadhav.

“At Jendamark, we are continuously looking for challenges. In fact, normal is boring at our company. We constantly strive for innovation. As a group, though, we had never worked in electric vehicles, so it was very exciting for all of us, especially in India, to get this opportunity. It was a complete white canvas project, which we started from scratch with concept development.”

Jadhav says Jendamark began the journey by securing two orders from Mahindra: one for the power electronics line and another for the power pack line.

“Power electronics consists of a charger, variable frequency drive (VFD) and all electrical signal processors which power the vehicle, while the power pack is a cluster of batteries put together as a pack which powers the vehicle.”

Outlining the partnership, Jadhav says Mahindra’s electric mobility group took a big leap into the future with the inauguration of its first Electric Technology Manufacturing Hub in Karnataka, India, late last year.

“Mahindra already have proven products and also the infrastructure. They have a strong strategy in place to further strengthen the portfolio by launching new electric vehicles,” he explains. Brands currently being produced by Mahindra include the e-KUV compact SUV, e-Supro van and e-Verito sedan, as well as the Treo – India’s first born-electric three-wheeler.

“Jendamark has proved a reliable partner in supporting their goals by delivering state-of-the-art, Industry 4.0-enabled assembly lines and solutions to their world-class facility in Bangalore.”

Because it is a relatively new field, Jadhav says he prefers to view any challenges faced by Jendamark as new opportunities. “This was the first time that any company was developing an automated assembly line in India for an Indian customer and we invested a lot of man hours in the beginning of the project to develop the right solutions.”

Looking to the future, Jadhav says JMKT is already at an advanced stage of discussions with a number of original equipment manufacturers (OEMs). “Having delivered India’s first automated assembly line for power pack electronics, we now fully understand the nuances of this business.”

by Good News Lab | Jun 7, 2019 | Industry 4.0, Jendamark Junction

Thinking about the future – and the possibilities that technology can unlock – is integral to Jendamark’s business success. Which is why the Group has invested in innovative start-up Closed-Loop Learner Network (CLN).

While the Fourth Industrial Revolution holds the promise of rapid economic development for Africa, it cannot succeed when millions of children have no access to a decent education or online resources. This is the problem that CLN sets out to solve with its Omang digital device.

Meaning “identity” in Setswana, Omang aims to give under-privileged youngsters a digital identity. It is a tablet that is sponsored by various corporate partners and pre-loaded with connectivity, CAPS curriculum-approved textbooks, white-listed online resources, tutorials and exam papers for Grades 10 to 12 learners.

Omang has been piloted among a thousand children in no-fee schools in the Free State and, with the endorsement of the provincial education department, that number is expected to grow to 20,000 by the end of the 2019 academic year.

CLN’s stated ambition is to place a fully resourced tablet in the hands of one million of the poorest pupils within the next five years.

“There are at least eight million children in under-resourced schools who have no teacher to inspire them, no access to a bigger world, no hope that there is something for them beyond mere survival,” says Jendamark sales and design director Yanesh Naidoo.

“That’s the reason we first started looking into Omang, as a way to open up their worlds and their minds.”

South Africa currently ranks a paltry 54 out of 63 global economies in the category of education and training, according to the latest IMD World Digital Competitiveness Rankings.

Naidoo says Jendamark converged with the technology-driven CLN on a number of fronts, ultimately leading to a 41% stake in the social entrepreneurial start-up.

“We are excited about this long-term partnership and we’re bringing our Odin software platform into the mix, which will provide the API for third-party app development.”

Such apps, he explains, could be used to teach additional life skills, such as financial literacy, while creating branding and interaction opportunities for corporate sponsors.

CLN founder Ajit Gopalakrishnan says the goal is to become “the Facebook of education” and to collect data to gain in-depth insight into the next generation in order to equip them for the future.

“It’s about seeing the human potential – and the business opportunity – in including the masses in the economic equation,” he says.

For Jendamark managing director Quinton Uren, however, the mission is a lot more personal. As a historically disadvantaged person, he says he knows how important it is to give children the tools to explore and dream and to see beyond their limiting reality.

“What we’ve been searching for at Jendamark is how to give back effectively. When Ajit presented this programme, I just knew: this rang true. We can digitise and give millions of children hope. This can be a real game-changer.”

Uren says the aim is not to repair South Africa’s underperforming education system, but to leapfrog it.

“Industry 4.0 is the perfect platform to achieve this. With this paperless tablet device, we can really change lives and the future of our country.”

by Good News Lab | May 23, 2019 | Jendamark Junction

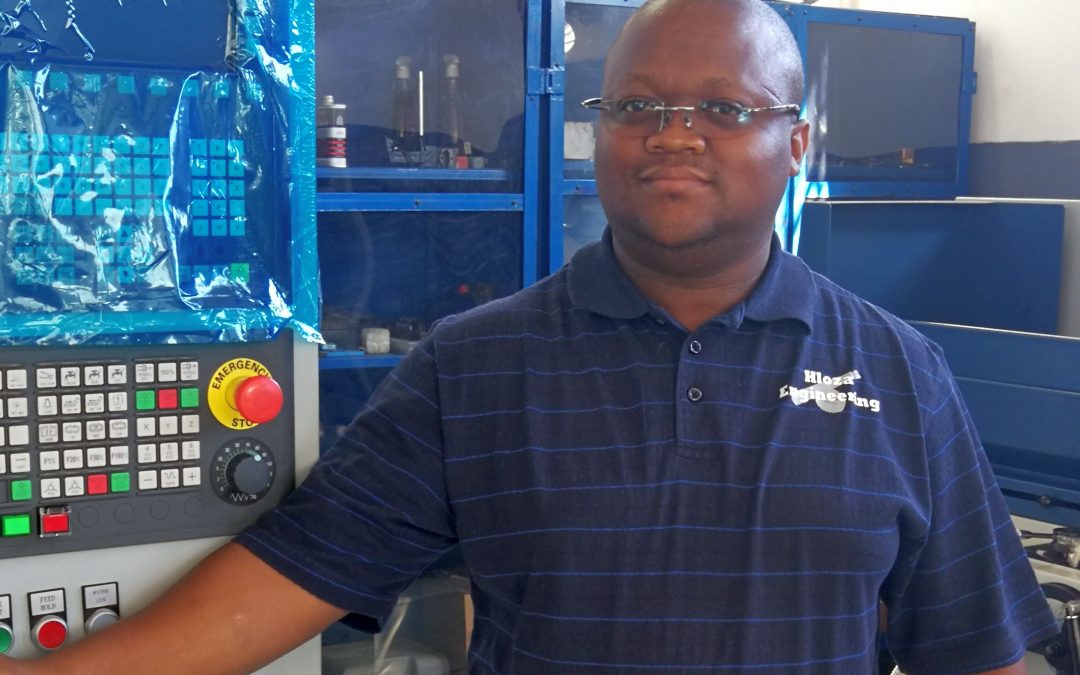

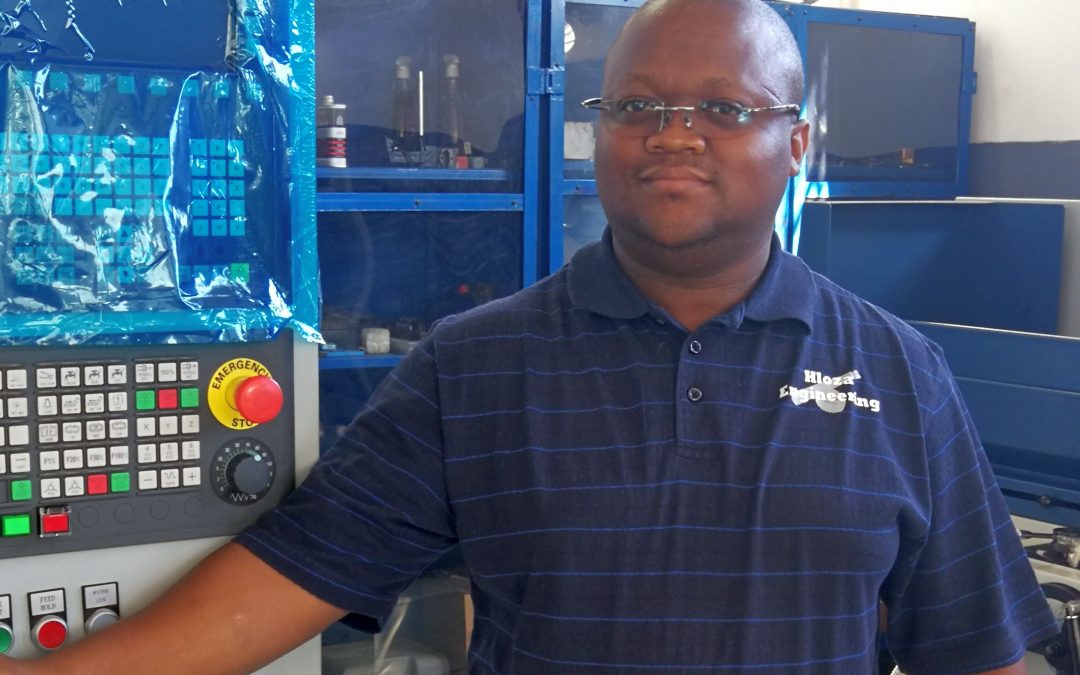

Jendamark-mentored supplier Phumzile Heshu shares how he overcame the odds and what drove him to become a successful businessman with his own engineering company.

As a young boy growing up in an impoverished area of Port Elizabeth, South Africa, Phumzile Heshu liked to play behind Continental Tyre. He would gaze at the massive tyre plant and vow that one day he would work there.

Although he was already driven by ambition, little did Heshu realise that his desire to succeed would one day see him reaching the point where his 10-year plan would be to list his recently established engineering company on the Johannesburg Stock Exchange.

Earlier this year, his business efforts saw him being awarded a R2.9-million grant from the Eastern Cape Department of Economic Development, Environmental Affairs and Tourism, which he used to buy a high-tech machine to increase manufacturing capacity.

Heshu’s Hloza Engineering was the only Port Elizabeth-based company to receive such funding.

“I am living the dream – but I would not have got where I am without the invaluable assistance I received over the past few years from Jendamark,” he says.

WILLING TO WORK

Heshu’s remarkable success story began at school where he may not have been the best scholar but worked tirelessly to achieve the desired results.

He went on to gain a diploma in mechanical engineering and then landed his dream job at Continental Tyre, where he worked as a mechanical technician for almost 17 years.

“But it was time to move on. I wanted to open my own business, so I bought a turning machine and approached a friend, Leroy Green of Modimad Engineering, asking if I could rent some of his machines. After he agreed, all I needed was clients.”

Almost instantly, brands such as Kanu Commercial Body Construction, Goodyear, Continental and Transnet came on board, offering Heshu the chance he desperately craved, but it was not enough, so he plucked up the courage to approach Jendamark.

HELPING HAND

“The Jendamark team were very receptive from the outset and agreed to give me work. While they were very happy with the products I was delivering, I was floundering and running up debts,” he says.

Struggling under the financial constraints, Heshu turned to Jendamark management for assistance. Seeing an opportunity to assist with sustainable small business development, they instantly offered to mentor him in growing his business and help him manage his finances.

A few months later, in 2017, he was doing so well that the decision was made to move away from Modimad and set up his own company – Hloza Engineering.

Once again, Jendamark came to the aid of the fledgling business, helping him to relocate to premises in Schadie Street in Schauderville.

Heshu has since moved across the road, where a modern workshop runs smoothly under his guidance.

EXPANSION PLANS

While he already manufactures steel and aluminium parts for Jendamark as well as Hloza’s other customers, Heshu is still a dreamer at heart and plans to expand even further.

“That was the whole point of the Bhisho grant, which was not easily secured. There were a lot of background checks, testimonials had to be produced and lots of questions asked,” says Heshu.

“When I learnt that I had secured it, I was over the moon. The funds allowed me to buy a state-of-the-art CNC [Computer Numerical Control] machine with a diverse range of functions.

“This, in turn, will allow me to increase capacity and, hopefully, take on more staff.”

When this happens, Heshu will remain true to his roots and offer other previously disadvantaged people the same opportunities Jendamark afforded him.

“When I couldn’t sleep at night for worrying, Jendamark cleared the path for me. They taught me to prioritise, how to control my finances and how to stay focused.

PAYING IT FORWARD

“While I am eternally grateful to them for helping me to realise my dream, I will know when it is time to leave the nest. That’s when it will be my turn to help others in the same way that Jendamark helped me.”

The Heshu family are all involved in building the business’s long-term success.

“My wife, Zoleka, is a director, taking the admin off my shoulders and all four of my children, from my eldest daughter to my youngest child, the only boy, are already a big part of the business,” Heshu says.

“They are the future of my company – one which, if all goes to plan, will be listed on the JSE within the next 10 years. One day I hope to operate on the same level as Jendamark, who gave me the courage to fulfil my dream. Now my dream is to pay it forward.”

by Good News Lab | Dec 11, 2018 | Jendamark News

This year, Jendamark Techcellency (JMKT) delivered a first for India and its biggest order to date – an innovative engine assembly line that uses augmented reality to guide its operators.

In May, this line was installed in the Skoda plant in Aurangabad, where it is being used to assemble four-cylinder R4 and six-cylinder V6 engines. The €2.5 million production line, which took 10 months to complete, has successfully produced the pilot series of engines and is currently gearing up for a ramp up in volumes.

JMKT operations director Himanshu Jadhav says the Industry 4.0-driven project was not just a first for the JMKT

team but for the customer too.

“As a turnkey project, it was extremely complex and many of the aspects had never been done before. Our engineers spent a considerable amount of time understanding the requirements, coming up with innovative solutions and making it work.

“This line has several unique solutions – from a mechanical, electrical and IT point of view – which showcase our

capabilities as a leading tech-oriented company,” says Jadhav.

First among these is the use of augmented reality glasses in the production environment to guide the operator through the assembly process. There is also the extensive use of tools and gauges that transfer critical production data via a wireless network.

“All of these Industry 4.0 solutions are based on our Odin software platform,” says Jadhav.

“We also gave our customers a realistic feel for the line and a chance to suggest improvements – before a single part was manufactured – using THEIA, our virtual reality solution.”

The complete line entailed the design and manufacture of more than 300 items required for the assembly of the engine in the most cost-effective way, without compromising on quality.

Teams from South Africa, Germany and India were involved in every aspect of the project from design to execution.

“The whole global team put in long, hard hours but our passion to deliver and an uncompromising approach towards results saw us execute this project to the best of our abilities and ensure customer satisfaction.”

by Good News Lab | Dec 7, 2018 | Jendamark News

Jendamark continues to push the boundaries of possibility with its longest and most automated powertrain production line so far. This differential assembly line is also the largest single-order project ever to be completed by the Group.

Designed to assemble the GM-A2xx platform differentials for General Motors, the line has been installed for ZF at their Gainesville facility in Georgia in the United States.

Jendamark’s head of powertrain assembly, Johan Labuschagne, says the project turnaround time was 12 months, as the entire line had to be designed from scratch.

“No existing machine designs could work for this specific product, except our pinion nut tightening machine, which also had to be modified,” says Labuschagne, adding that it was the first full differential assembly line supplied by Jendamark in 15 years.

“Our R&D experts guided the design team and from there we relied on our vast experience with manufacturing, assembly and commissioning to bring this production line to life.”

It was also the first line to use the latest version of Jendamark’s production and line management software, Odin.

This was particularly important as the assembly process involves gauging to select the right parts for optimum performance of the differential unit, and testing – including a backlash measurement and leak testing – to verify that the assembly process was done correctly.

“Its value has been proven, and we have received an order for another production line using Odin from the same customer,” says Labuschagne.

“We faced some serious hurdles, but the team put in the necessary research and hours to get the project over the finish line. Everyone can feel proud that we delivered a good product and won the customer’s confidence for future projects.”

THE BIG NUMBERS:

Total floor area: 50m x 22m

Total conveyor length: 130m

Machine footprint: 46m

Design: Loop conveyor system

Working stations: 18

Operators: 8

Robots: 5 (plus 1 installed by customer)